Examples from practice

Technical solutions for individual plant systems

We supply our customers with technical solutions that are individually adjusted to their plant systems, in order to meet the high requirements of the different application areas of water treatment.

Dosing technology

Reliable and economical dosing

Opting for process-based dosing technology will ensure that water treatment is successfully performed in a targeted and economic manner. Microprocessor-controlled magnet diaphragm dosing pumps allow for all control variants to be configured according to the plant’s specific requirements. The standardised material selection for components with medium contact is suitable for all types of chemicals that require dosing. The output range can be set to 0.74 to 75 litres per hour with counter-pressure ranging from 25 to 2 bar. It can be accurately adjusted via stroke length and frequency. Only one movable part is required for dosing, owing to the dosing pump’s constructive design. This means that the drive system is almost wear-free.

Cooling water controllers

Reliable measuring, controlling and regulating

The new cooling water controller WCT 600 offers state-of-the-art technology and contributes to durable and low-loss operations of recooling plants. Two individually configurable sensor inputs (e.g. conductivity and bromine), two integrated biocide timers featuring adjustable preliminary desalination and desalination blocking, six digital inputs, six relay outputs and integrated data storage, provide that the requirements according to the recommendations of VDI 2047-2 regarding hygiene for recooling plants are met.

The integrated USB interface can be used for reading out the data memory, for importing and exporting configuration tables and for updating controller software.

Via an Ethernet card, it is also possible to connect the device to a LAN or a gateway for internet access.

The WCT 600 comes with a PVC measuring section that includes the inductive conductivity sensor, sample water monitoring and a sampling tap, installed on a mounting panel and ready to use.

Softening

Cabinet plants

Fully automated water softening plant with a compact design and an integrated brine tank. Control valve with blending valve and GFRP pressure tank including top-quality cation exchanger.

Nominal flow: between 0.16 and 1.2 m³/h

Individual plants

Fully automated water softening plant with 5-step central control valve, controlled by time, volume or microprocessor. GFRP pressure tank including top-quality cation exchanger. Brine tank with sieve bottom and integrated float valve.

With central control valve FL-2750 / 1"

Nominal flow: between 0.66 and 1.2 m³/h

With central control valve FL-2850 / 1½"

Nominal flow: between 4.4 and 10 m³/h

Twin plants

Fully automated water softening plant with 5-step central control valve, controlled by time, volume or microprocessor. GFRP pressure tank including top-quality cation exchanger. Brine tank with sieve bottom and integrated float valve.

With central control valve FL-9000 / 1"

Nominal flow: between 0.6 and 4 m³/h

With central control valve FL-9500 / 1½"

Nominal flow: between 4.4 and 8 m³/h

With central control valve FL-2900 / 2"

Nominal flow: between 8 and 18 m³/h

With central control valve FL-2900 / 3"

Nominal flow: between 20 and 30 m³/h

UV technology

Physical water disinfection

The UV devices are used to ensure water quality for evaporative cooling systems and air washers (circulation spray humidifiers). All UV devices benefit from the high standards of DVGW (German Association for Gas and Water) certification for approved devices for drinking water disinfection. The UV devices feature self-monitoring functions and are designed for unattended operation. The devices are therefore well suited for use in automated systems. All required monitoring parameters such as integrated UV monitoring, alarm device with limit values and operating hours are saved in real-time via the integrated data logger and are included in the standard configuration. This means that all documentation requirements are taken care of in addition to successful disinfection.

Application for evaporative cooling systems:

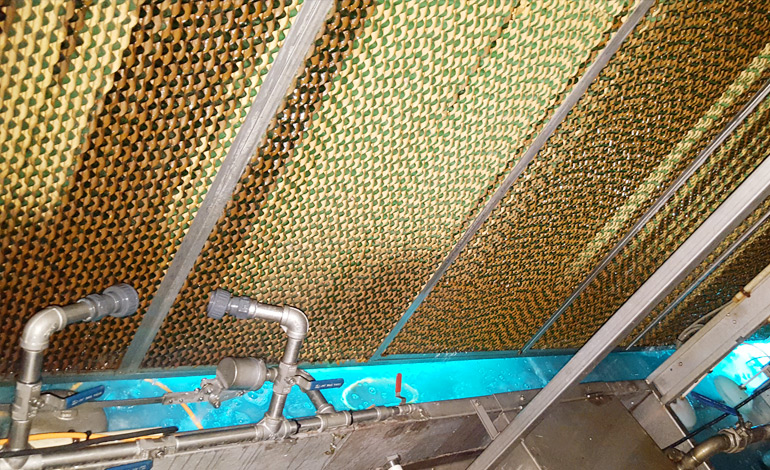

In a chamber, water from above drips or is sprayed vertically against a rising air current from below. Part of the water evaporates for the purpose of adiabatic cooling, the excess water is gathered in a tub or a tray on the ground. A UV device is located in this tub / tray, where it disinfects the water through high-energy UV light. As an alternative, flow-through UV devices can be installed in the circulation system leading to the spray nozzles or dripping outlets.

Application for circulation spray humidifiers:

With a pressure of about 3 bar, water is sprayed horizontally against an air current in a chamber. Part of the water evaporates (adiabatic cooling), the other part washes the air and is gathered in a tub at the bottom of the system. The UV device is located in this tub, where it disinfects the water through high-energy UV light.

General risk:

Evaporative cooling systems may release aerosols containing legionella bacteria, which may lead to severe pneumonia and even death when inhaled. Risks can arise for both staff members working in the environment of aerosol generating units and for completely unrelated individuals, if aerosols are carried in the air. This is why all systems bearing hot water must comply with hygiene requirements to prevent health hazards.