UV technology

UV technology

Physical water disinfection

The UV devices are used to ensure water quality for evaporative cooling systems and air washers (circulation spray humidifiers). All UV devices benefit from the high standards of DVGW (German Association for Gas and Water) certification for approved devices for drinking water disinfection. The UV devices feature self-monitoring functions and are designed for unattended operation. The devices are therefore well suited for use in automated systems. All required monitoring parameters such as integrated UV monitoring, alarm device with limit values and operating hours are saved in real-time via the integrated data logger and are included in the standard configuration. This means that all documentation requirements are taken care of in addition to successful disinfection.

Application for evaporative cooling systems:

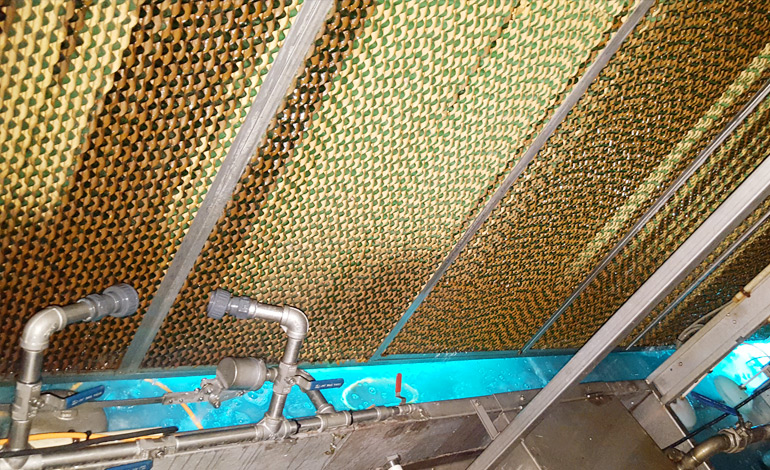

In a chamber, water from above drips or is sprayed vertically against a rising air current from below. Part of the water evaporates for the purpose of adiabatic cooling, the excess water is gathered in a tub or a tray on the ground. A UV device is located in this tub / tray, where it disinfects the water through high-energy UV light. As an alternative, flow-through UV devices can be installed in the circulation system leading to the spray nozzles or dripping outlets.

Application for circulation spray humidifiers:

With a pressure of about 3 bar, water is sprayed horizontally against an air current in a chamber. Part of the water evaporates (adiabatic cooling), the other part washes the air and is gathered in a tub at the bottom of the system. The UV device is located in this tub, where it disinfects the water through high-energy UV light.

General risk:

Evaporative cooling systems may release aerosols containing legionella bacteria, which may lead to severe pneumonia and even death when inhaled. Risks can arise for both staff members working in the environment of aerosol generating units and for completely unrelated individuals, if aerosols are carried in the air. This is why all systems bearing hot water must comply with hygiene requirements to prevent health hazards.